HOMEmade - family houses in Bangladesh

These three family houses are the results of a hands-on workshop for students and young architects conducted in a remote rural area of Bangladesh. Eight students of the BRAC University in Dhaka (Bangladesh) as well as five Students from the University of Art in Linz/ projectstudio BASEhabitat (Austria) came to a small and remote village in the North of Bangladsh, Rudrapur, to continue what has started with the Handmade METI-School: to work together with the local people on a model for a sustainable, modern architecture in a dynamic process. The goal of the HOMEmade project is to improve the living conditions of the local population and to strengthen national identity while maintaining the current high level of sustainability with regard to home construction. This is accomplished by building three model houses for low-income village families designed by young local architects and built by local craftsmen who have been trained in the modern mud and bamboo building techniques. It is the expectation that the young architects will be able to carry their knowledge and skills to other regions of Bangladesh and the trained labor will be able to use their skills to build other modern mud homes in the region.

Bangladesh is one of the most densely populated countries in the world; approximately 1,045 people per square kilometer. Each year more and more agricultural land is lost to residential development. If Bangladeshis in the rural areas (about 110 million people) started living in two story structures, more land would be available for farming. This would help reduce some of the food shortage problems that the country is currently facing.

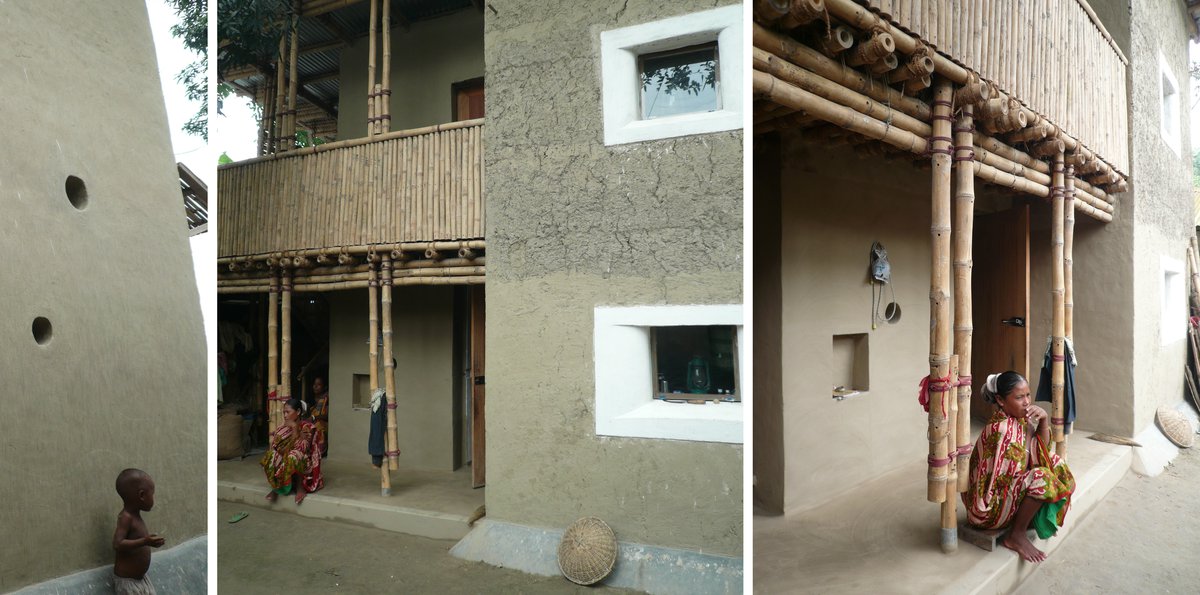

All three family houses conform to both the traditional and contemporary lifestyles of rural low-income families, but have incorporated design and construction features that improve comfort, safety, durability, and privacy. As in traditional vernacular Bangladeshi architecture, the kitchen and bathroom are still housed in separate structures. The new buildings have two stories, however, which double the family living area while maintaining the same building footprint. The land saved by adding the second story can be used as a small house garden. The second story provides a new experience of view and privacy while still being connected to the rest of the household.

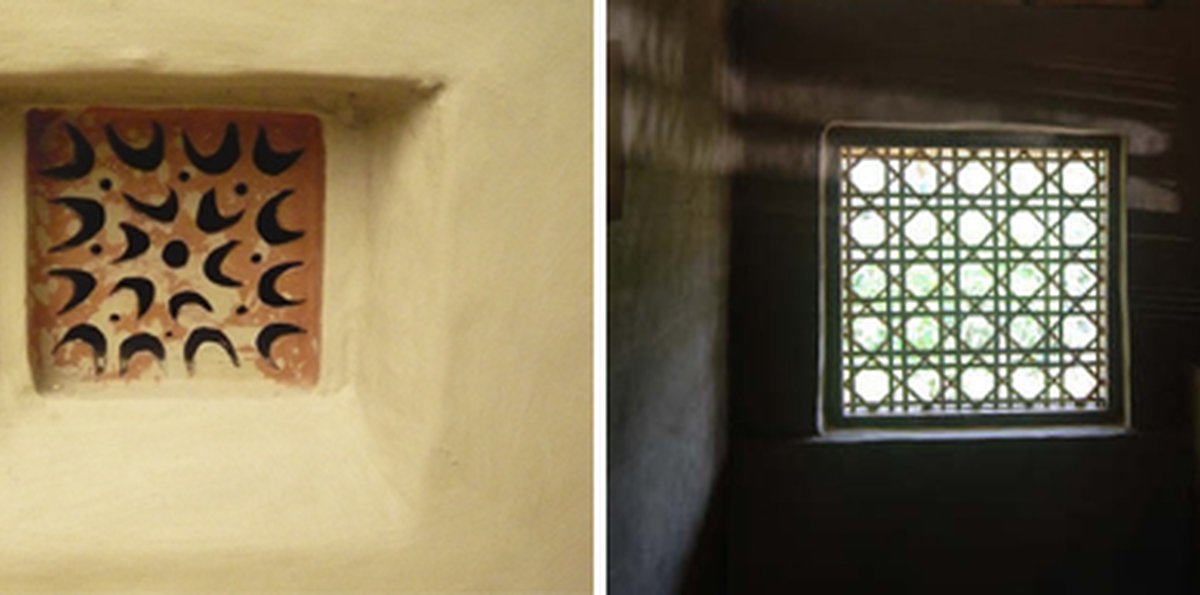

Roof thermal masses, coconut fiber insulation, glass windows, and openings designed for cross ventilation assure that the indoor temperature is comfortable year round. Most of the existing Bangladeshi mud houses are too cold in the winter because cold air comes in through the openings and hot air escapes through the roof. They are also too hot in the summer because the uninsulated CI sheet roofs quickly heat up the interior and poor ventilation does not allow the hot air to escape. The new building technologies also significantly increase the durability and lifespan of the mud homes. Local materials were used even more radical than the METI school in order to reduce costs: rammed earth foundations with a thin layer of Ferro-cement and a damp proof course prevent pests from burrowing into the buildings and moisture from seeping up from the ground into the walls. Small pieces of bamboo strategically placed on the exterior walls act as speed breakers to prevent rain erosion. And straw mixed in with the mud increases wall cohesion and strength. Instead of nylon ropes like in the METI-school, ropes made of coconut fibre were used and bamboo dowels instead of steel wherever it was possible.

Find more informations: FUTUREARC - HOME-made family houses by AH

Funded by: Shanti-Partnerschaft Bangladesh e.V.

Implemented through:Dipshikha (Non-formal Education Training and Research Society for Village Development)

Buildings:

Floor area: about 45 m2

Location: Rudrapur and Vinshnupur, Dinajpur district, Bangladesh

Clients: Familiy Shepal Depsharma, Family Hemonto Ray and Family Rahini Ray

Participating students:Students of BRAC University Dhaka, Bangladesh (16 weeks): Adrita Anwar, Shoeb Al-Rahe, Tanmay Chakrabarty, Omar Faruque, Majeda Khatun, Imrul Kayes, Gazi Fazle Rahim, Suvashis Saha

Concept: Anna Heringer and Paul Ch. Tigga

Design: students of BRAC University Bangladesh and University of Art and Industrial Design Linz, Austria

Supervision design: Anna Heringer, Khondaker Hasibul Kabir

Structural engineering and technical supervision: Stefan Neumann

Energy concept: Oskar Pankratz

Advisor in earthen structures:Martin Rauch

Advisor in bamboo treatment and quality management: Prof. Walter Liese

Supervision of site: Stefan Neumann, Montu Ram Saw, Azit Ray and the students

Project-management: Anna Heringer with Dipshikha

Duration:

The construction workers and craftsmen were are all coming from Rudrapur and Vishnupur.

This project is part of the Phd of Anna Heringer with kind support of The Elite Network Bavaria